Author:FTM Date:2024/07/08

Definition: Construction waste is the discarded soil, materials, and other waste generated during the construction, renovation, expansion, and demolition of various buildings, structures, pipelines, etc., by construction units and residents decorating and renovating houses.

According to the origination, construction waste can be categorized into five types: land excavation, road excavation, demolition of old buildings, building construction, and construction material production waste. It mainly consists of soil, rubble, waste mortar, broken bricks and tiles, concrete blocks, asphalt blocks, waste plastic, waste metal materials, waste bamboo, and wood.

① Massive Volume and Potential of Global Construction Waste: Data shows that with the development of industrialization and urbanization, the annual generation of construction waste worldwide has exceeded 2 billion tons, accounting for more than half of all waste produced.

② Increasing Complex Components of Construction Waste Composition: Currently, construction waste not only includes traditional building materials such as concrete, wood, and glass but also other industrial materials ranging from computer hardware to household appliances, paint, and chemical reagents.

a. The surge in construction waste not only severely pollutes the natural environment but also hinders sustainable economic and social development. Effectively mitigating the hazards of construction waste and achieving green development has become a major breakthrough point for the transformation of the construction industry.

b. Hazards of construction waste: Occupies a large amount of land resources; causes traffic congestion and energy consumption; harms the environment, leading to soil and water pollution; poses significant safety risks.

c. Severe shortcomings of traditional treatment methods: Traditional methods of dealing with construction waste mainly include piling, landfill, and backfilling. However, these methods greatly impact the environment, causing soil pollution, groundwater contamination, and air pollution.

Recycling construction waste has become a new attempt, and it is possible to reuse materials by using FTM stone crushers. Concrete waste can be crushed and screened to produce recycled aggregates, which can be used for road base, wall filler materials, and products such as porous bricks, hollow slabs, hollow blocks, and cement raw materials. Waste wood can be used to manufacture synthetic boards, and asphalt can be regenerated after recycling.

Concrete is currently the most valuable part of construction waste for recycling. Recycled aggregates produced from waste concrete are favored in the market due to their high strength and low production cost. These recycled aggregates, when mixed and compacted according to certain gradations, have a high bearing capacity and can be directly used in projects such as soft foundation treatment, shaft backfill, subgrade cushion, water treatment, and site dust suppression. They can also partially or completely replace natural aggregates to produce recycled inorganic mixtures, recycled bricks, and recycled concrete.

FTM Company has professional experience in the research and production of stone crushing equipment. FTM stone crushers have been shipped to many cities and countries domestically and internationally, receiving widespread acclaim for their quality and service. With forty years of quality assurance, FTM is a trustworthy choice.

Features: Complete process stages, long approval process, long construction period, large investment scale, large footprint, requires long-term material sources, high environmental standards, dust can be handled in an enclosed space, can serve as urban infrastructure, typically paired with recycled product production lines.

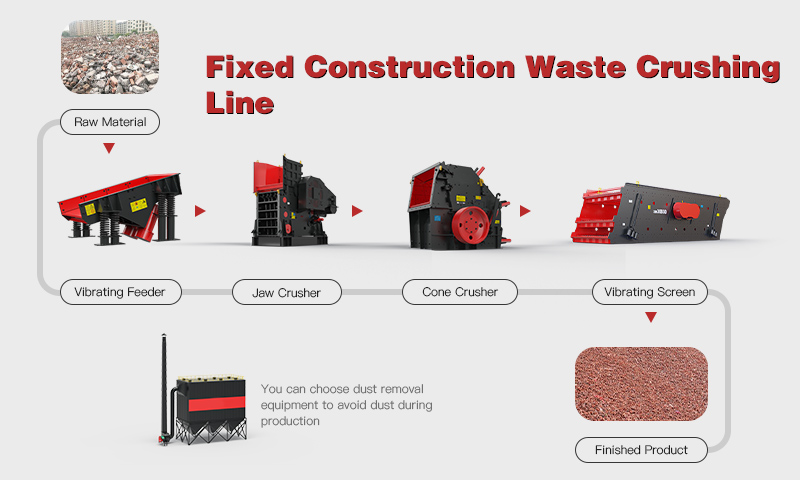

Hard Material: Pre-screening Combination Feeder + Jaw Crusher + Cone Crusher + Vibrating Screen

Soft Material: Pre-screening Combination Feeder + Jaw Crusher + Impact Crusher + Vibrating Screen

Features: Simple process stages, short construction period, flexible site transition, convenient for dispersed and on-site centralized disposal, requires dust removal equipment.

Required Equipment: Mobile crushing station + dust removal equipment.

The role of new crushing and screening equipment is becoming increasingly prominent, and the relevant market is set to experience breakthrough development. With the maturation and standardization of urban construction waste management, as well as the growing environmental awareness among people, the recycling of construction waste has been implemented nationwide.

The role of new crushing and screening equipment in the field of construction waste management is becoming increasingly significant, and the relevant market is expected to see significant growth. Most of the aggregates processed from construction waste can be reused in road construction, real estate projects, urbanization construction, and landscaping, holding high economic utilization value.

The global construction industry is expected to continue its relatively rapid development in the future, but the progress of construction waste resource utilization has been severely lagging. However, with strong support from various countries in promoting the resource utilization of construction waste and the acceleration of various construction waste resource utilization projects, the future prospects of the construction waste management industry are promising.

FTM Company offers free design and quotes for various models of crushers and auxiliary equipment. With a complete range of models and comprehensive configurations, we provide free services including surveying, design, installation, and after-sales support, helping users achieve higher returns at lower costs. We welcome you to consult online for free or visit our factory in person.