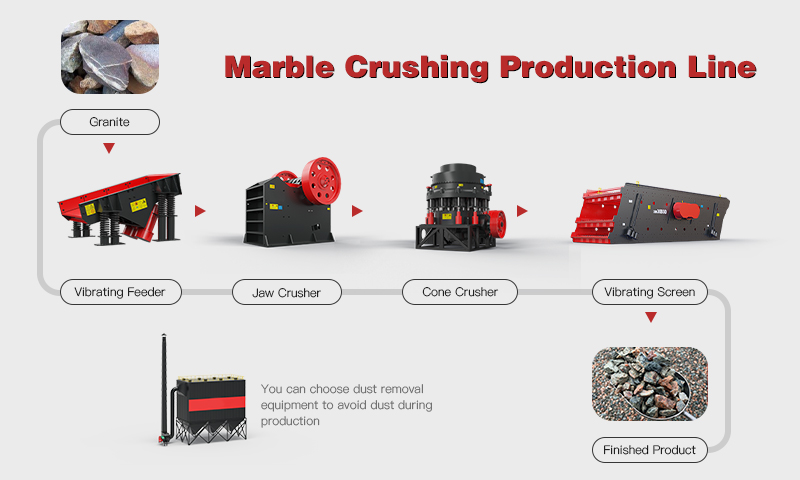

Granite processing technology in China has indeed become quite advanced. FTM Company has developed comprehensive production lines for granite crushing, which cater to the diverse needs of customers across various regions. Here's a summary of the typical process and equipment involved.

- Two-Stage Crushing Process:

Material Feeding: Vibrating Feeder- Evenly feeds large pieces of granite into the crusher.

First Stage: Jaw Crusher- Handles coarse crushing of granite.

Second Stage: Impact Crusher- Further crushes the stone to finer granularity.

- Separation: Vibrating Screen- Screens and separates different specifications of stones (1-2, 2-4, 4-8, etc.)

Optional Equipment: Cone Crusher and Dust Removal Equipment.

Design Output: Typically ranges from 50 to 500 tons per hour.

Customization: Production lines can be tailored to meet specific customer requirements, including different stone specifications and additional equipment for dust removal and environmental protection.

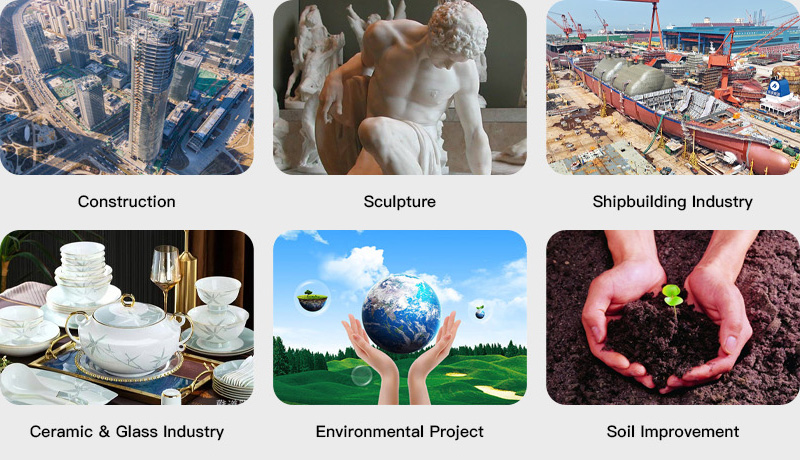

Granite's unique properties make it an excellent choice for various construction applications, contributing to the continuous demand and development in China's stone machinery industry. The well-designed production lines by companies like FTM ensure efficient and high-quality granite processing, meeting the growing needs of the infrastructure sector.