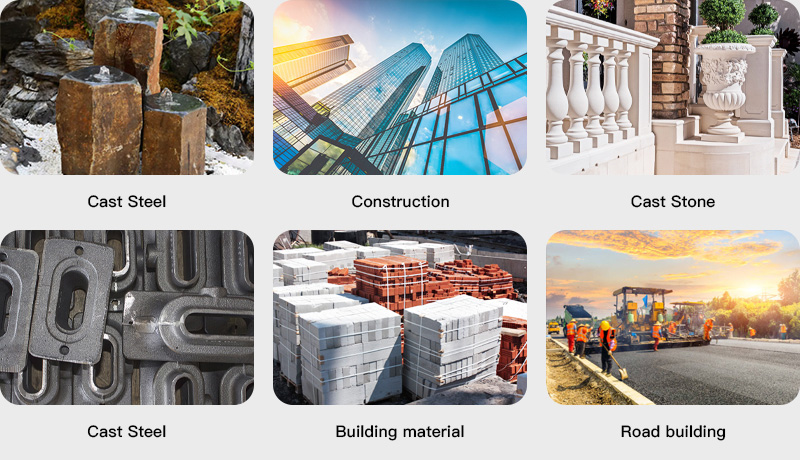

Basalt is a valuable material in construction and various industrial applications due to its exceptional properties. Properly designing the crushing process and selecting appropriate equipment are crucial to manage the high abrasion and production costs associated with basalt. FTM Group, a leading crusher manufacturer, provides a full set of advanced basalt crushing equipment and comprehensive support to ensure efficient and profitable operation.

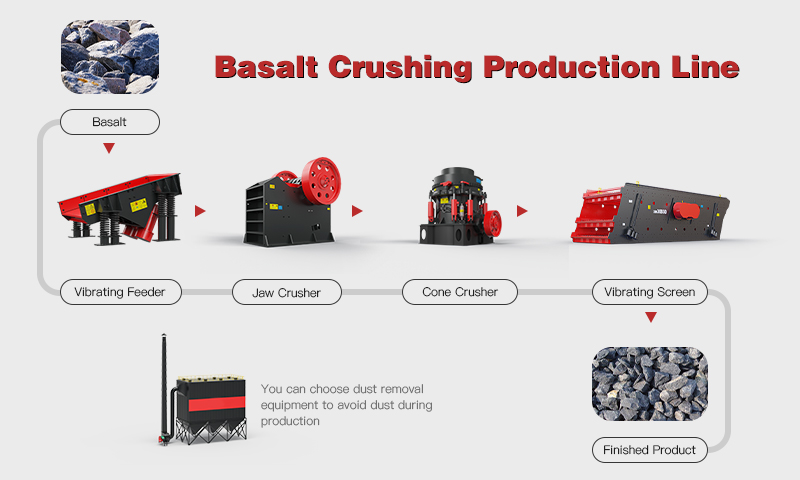

1. Lamination Crushing Equipment: To reduce wear and tear, equipment that utilizes the lamination principle is preferred. This includes:

- Two-Stage Jaw Crusher: Utilizes a primary jaw crusher followed by a secondary jaw crusher.

- Jaw Crusher + Cone Crusher: A primary jaw crusher followed by a cone crusher for secondary crushing.

2. Tertiary Crushing and Shaping:

- Impact Crusher: Used in the tertiary crushing stage mainly for shaping the material, ensuring good grain shape while reducing abrasion costs.

3. Process Configurations:

- Coarse Jaw Crusher + Fine Jaw Crusher/Cone Crusher: If specific grain sizes are required, this configuration is considered to balance wear costs and product quality.

Conclusion:Basalt is a valuable material in construction and various industrial applications due to its exceptional properties. Properly designing the crushing process and selecting appropriate equipment are crucial to manage the high abrasion and production costs associated with basalt. FTM Group, a leading crusher manufacturer, provides a full set of advanced basalt crushing equipment and comprehensive support to ensure efficient and profitable operation.