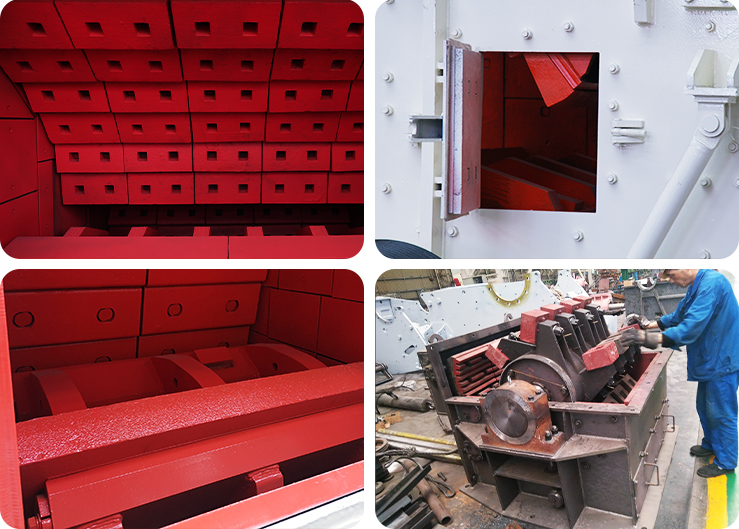

The PF series impact crusher has unique structural design and advanced manufacturing process. And it is widely used for low-abrasive materials crushing with medium hardness or less in industries such as railways, highways, energy, building materials, and chemical industry.

| Model | Specifications(mm) | Feed Openting(mm) | Maximum Feeding size(mm) | Capacity(t/h) | Power(KW) | Dimensions L×W×H(mm) |

| PF1007 | ø 1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330×1660×2300 |

| PF1010 | ø 1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370×1700×2390 |

| PF1210 | ø 1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680×2160×2800 |

| PF1214 | ø 1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650×2460×2800 |

| PF1315 | ø 1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180×2720×3120 |

| PF1320 | ø 1320×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220×3100×3120 |

| PF1520 | ø 1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959×3564×3330 |

| PF1820 | ø 1800×2000 | 1260×2040 | 800 | 300-800 | 4P 630-710 | 4400×3866×4009 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Feed Openting(mm) | Capacity(t/h) |

| PF1007 | 400×730 | 30-70 |

| PF1010 | 400×1080 | 50-90 |

| PF1210 | 400×1080 | 70-130 |

| PF1214 | 400×1430 | 80-180 |

| PF1315 | 860×1520 | 100-280 |

| PF1320 | 993×2000 | 140-380 |

| PF1520 | 830×2040 | 200-550 |

| PF1820 | 1260×2040 | 300-800 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Online Chat

Scheme Determination

Solution Design

Products Manufacturing

Express Transportation

Installation Guidance

Fast Production