The SC series cone crusher excels in high performance with features such as high efficiency, excellent particle shape, hydraulic adjustment, remote automation control, multiple optional crushing chambers, and adjustable eccentricity without part replacement.

SC Single Cylinder Cone Crusher Medium Crushing Series

| Model | Cavities | Feeding Size (mm) | Maximum Feeding Size (mm) | Minimum Discharging Size (mm) | Power (kw) | Capacity(t/h) |

| SC100S | C1 | 240 | 175 | 22 | 90 | 85-170 |

| C2 | 200 | 160 | 19 | 70-130 | ||

| SC160S | C1 | 360 | 290 | 25 | 160 | 125-345 |

| C2 | 300 | 240 | 22 | 108-305 | ||

| SC250S | C1 | 450 | 360 | 35 | 250 | 265-524 |

| C2 | 400 | 320 | 29 | 225-448 | ||

| SC315S | C1 | 560 | 450 | 41 | 315 | 349-1050 |

| C2 | 500 | 400 | 38 | 318-892 | ||

| SC450S | C1 | 600 | 480 | 44 | 450 | 498-1500 |

| C2 | 480 | 385 | 41 | 454-1274 |

SC Single Cylinder Cone Crusher Fine Crushing Series

| Model | Cavities | Feeding Size (mm) | Maximum Feeding Size (mm) | Minimum Discharging Size (mm) | Power (kw) | Capacity(t/h) |

| SC100 | F1 | 150 | 120 | 10 | 90 | 45-135 |

| F2 | 90 | 70 | 10 | 43-118 | ||

| F3 | 50 | 40 | 6 | 25-40 | ||

| SC160 | F1 | 200 | 160 | 13 | 160 | 69-215 |

| F2 | 115 | 90 | 10 | 57-184 | ||

| F3 | 75 | 60 | 8 | 70-90 | ||

| SC250 | F1 | 240 | 190 | 16 | 250 | 116-396 |

| F2 | 140 | 110 | 13 | 97-346 | ||

| F3 | 70 | 55 | 9 | 90-251 | ||

| SC315 | F1 | 275 | 220 | 32 | 315 | 177-662 |

| F2 | 215 | 170 | 29 | 209-643 | ||

| F3 | 175 | 140 | 29 | 162-552 | ||

| F4 | 85 | 70 | 19 | 175-325 | ||

| SC560 | F1 | 300 | 240 | 22 | 560 | 448-1512 |

| F2 | 195 | 155 | 19 | 380-1373 | ||

| F3 | 90 | 70 | 13 | 357-912 | ||

| SC750 | F1 | 370 | 295 | 25 | 750 | 394-2181 |

| F2 | 300 | 240 | 19 | 342-2020 | ||

| F3 | 230 | 185 | 16 | 267-1814 | ||

| F4 | 120 | 95 | 13 | 248-1165 | ||

| F5 | 85 | 70 | 10 | 185-1170 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

SC Single Cylinder Cone Crusher Medium Crushing Series

| Model | Cavities | Feeding Size (mm) | Capacity(t/h) |

| SC100S | C1 | 240 | 85-170 |

| C2 | 200 | 70-130 | |

| SC160S | C1 | 360 | 125-345 |

| C2 | 300 | 108-305 | |

| SC250S | C1 | 450 | 265-524 |

| C2 | 400 | 225-448 | |

| SC315S | C1 | 560 | 349-1050 |

| C2 | 500 | 318-892 | |

| SC450S | C1 | 600 | 498-1500 |

| C2 | 480 | 454-1274 |

SC Single Cylinder Cone Crusher Fine Crushing Series

| Model | Cavities | Feeding Size (mm) | Capacity(t/h) |

| SC100 | F1 | 150 | 45-135 |

| F2 | 90 | 43-118 | |

| F3 | 50 | 25-40 | |

| SC160 | F1 | 200 | 69-215 |

| F2 | 115 | 57-184 | |

| F3 | 75 | 70-90 | |

| SC250 | F1 | 240 | 116-396 |

| F2 | 140 | 97-346 | |

| F3 | 70 | 90-251 | |

| SC315 | F1 | 275 | 177-662 |

| F2 | 215 | 209-643 | |

| F3 | 175 | 162-552 | |

| F4 | 85 | 175-325 | |

| SC560 | F1 | 300 | 448-1512 |

| F2 | 195 | 380-1373 | |

| F3 | 90 | 357-912 | |

| SC750 | F1 | 370 | 394-2181 |

| F2 | 300 | 342-2020 | |

| F3 | 230 | 267-1814 | |

| F4 | 120 | 248-1165 | |

| F5 | 85 | 185-1170 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Online Chat

Scheme Determination

Solution Design

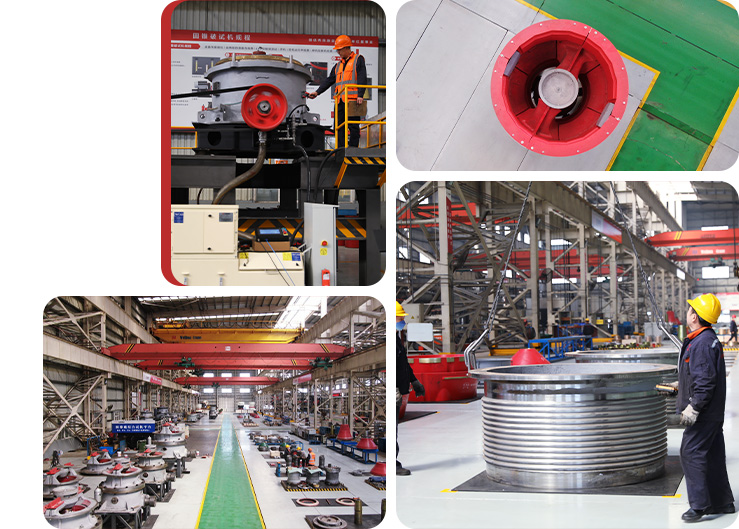

Products Manufacturing

Express Transportation

Installation Guidance

Fast Production