The SC/H800i series single-cylinder cone crusher inherits the SC series advantages with a larger eccentric distance, increased rotation speed, and a high crushing ratio chamber. This enhances throughput and product rate while reducing energy consumption. It also integrates advanced IoT concepts for 24/7 connectivity, improving productivity, predicting performance, and maximizing equipment uptime.

| Model | Cavities | Feeding Size (mm) |

Maximum Feeding Size (mm) |

Minimum Discharging Size (mm) |

Processing Capacity (t/h) |

Power (kw) |

| SC840i | C1 | 431 | 345 | 25 | 230-659 | 315 |

| C2 | 345 | 275 | 22 | 212-645 | ||

| SH830i | F1 | 211 | 169 | 13 | 113-283 | 250 |

| F2 | 93 | 74 | 8 | 84-212 | ||

| F3 | 61 | 49 | 5 | 61-139 | ||

| SH840i | F1 | 250 | 200 | 16 | 162-371 | 315 |

| F2 | 159 | 127 | 16 | 187-406 | ||

| F3 | 73 | 58 | 10 | 126-232 | ||

| SH860i | F1 | 315 | 252 | 16 | 259-799 | 500 |

| F2 | 169 | 135 | 16 | 281-867 | ||

| SH865i | F3 | 85 | 68 | 10 | 179-468 | |

| SH870i | F1 | 350 | 280 | 25 | 392-1173 | 630 |

| F2 | 184 | 147 | 19 | 351-1195 | ||

| F3 | 99 | 79 | 13 | 236-747 | ||

| SH890i | F1 | 428 | 342 | 25 | 488-1670 | 800 |

| F2 | 302 | 242 | 22 | 524-1789 | ||

| F3 | 219 | 175 | 19 | 460-1677 | ||

| SH895i | F4 | 112 | 90 | 13 | 291-910 | |

| F5 | 89 | 71 | 10 | 258-839 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Cavities | Feeding Size (mm) |

Processing Capacity (t/h) |

| SC840i | C1 | 431 | 230-659 |

| C2 | 345 | 212-645 | |

| SH830i | F1 | 211 | 113-283 |

| F2 | 93 | 84-212 | |

| F3 | 61 | 61-139 | |

| SH840i | F1 | 250 | 162-371 |

| F2 | 159 | 187-406 | |

| F3 | 73 | 126-232 | |

| SH860i | F1 | 315 | 259-799 |

| F2 | 169 | 281-867 | |

| SH865i | F3 | 85 | 179-468 |

| SH870i | F1 | 350 | 392-1173 |

| F2 | 184 | 351-1195 | |

| F3 | 99 | 236-747 | |

| SH890i | F1 | 428 | 488-1670 |

| F2 | 302 | 524-1789 | |

| F3 | 219 | 460-1677 | |

| SH895i | F4 | 112 | 291-910 |

| F5 | 89 | 258-839 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Online Chat

Scheme Determination

Solution Design

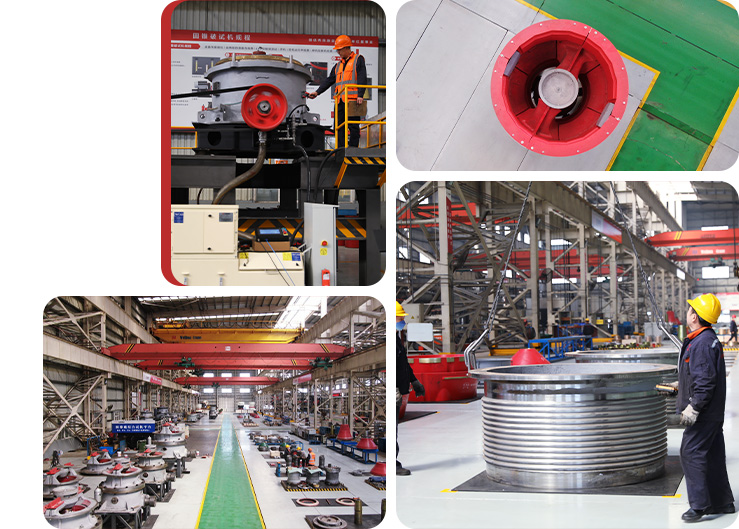

Products Manufacturing

Express Transportation

Installation Guidance

Fast Production