Author:FTM Date:2023/12/14

A quarry is an operation dedicated to the extraction and processing of construction-grade sand and gravel. These sites are typically expansive, open-pit areas and are usually located in regions abundant in rock formations, often found in hilly or mountainous terrain. Quarries are considered productive industrial units specializing in mining and refining construction materials. The production process of sand and gravel involves two main stages: extraction and refining (including grading and sorting). Fixed facilities within the quarry are primarily used for storage and grading. A medium-sized production enterprise can produce tens of thousands of tons of sand and gravel annually, while large enterprises have an annual production capacity reaching millions of tons.

FTM Company provides a wide range of quarry equipment, offering an extensive selection of high-quality products. We welcome online inquiries or visits to our factory.

Primary Sand and Gravel Equipment

The jaw crusher is a common crushing device used in mining production, mainly suitable for primary and secondary crushing of materials. Due to its simple structure and reliable operation, it is well-received by customers. Our company's jaw crushers have a compressive strength of 320 MPa.

A cone crusher is a secondary crushing equipment suitable for crushing various ores and rocks with medium or higher hardness, used for medium or fine crushing. It performs layered crushing, achieving selective crushing of materials with excellent finished particle shape. It is equipped with an overload protection device, which allows foreign objects such as iron blocks to pass through the crushing chamber without damaging the machine

An impact crusher is primarily used for the next stage of crushing (medium and fine crushing) following a jaw crusher, mainly suitable for crushing soft materials. It can handle various coarse, medium, and fine materials with a side length not exceeding 500mm and a compressive strength not exceeding 350MPa (such as granite, limestone, and concrete). It is widely used in the crushing of various ores, and in the production of artificial sand and gravel for the railway, highway, and construction industries.

A gyratory crusher is a primary crusher. Compared to a jaw crusher, its advantage is that the crushing process is carried out continuously along the annular crushing chamber, resulting in higher productivity, lower power consumption, and stable operation. It is suitable for crushing flaky materials. From the finished particle size distribution curve, it can be seen that the particle size of the finished product that exceeds the width of the discharge opening is smaller and less frequent than that of a jaw crusher, with a more uniform particle size. Gyratory crushers are suitable for use in large-scale production plants and quarries, with a handling capacity of 2000-10000 tons per hour.

Also known as a hammer mill, it is used for medium and fine crushing, performing layered crushing without the need for primary and secondary crushing, achieving one-time molding with a small discharge particle size. The hammer crushers PCZ and PCX are more expensive and have a larger output, capable of reaching 3200 tons, suitable for handling brittle materials.

A sand making machine is used to crush stones and produce sand, widely used in industries such as construction, roads, bridges, and chemicals. Depending on the working principle and application scenarios, sand making machines can be divided into various types. Our company's products mainly include: VSI sand making machine (vertical shaft impact crusher), impact sand making machine, compound crusher, fine crusher, double-stage crusher, and roller crusher.

Other Auxiliary Equipment

A vibrating feeder ensures that materials are uniformly and steadily fed into crushers, screens, or conveyor belts, preventing overloading or underloading of the receiving equipment. Additionally, during material transportation, the vibrating feeder can screen out small impurities and dust from the materials, improving the efficiency of subsequent equipment and the quality of the final products.

A vibrating screen separates materials by different particle sizes through screening and grading, thereby removing impurities, controlling particle size, achieving dehydration, and material separation, which improves production efficiency and product quality. Our company's products mainly include: circular vibrating screens and HX series heavy-duty vibrating screens.

A sand washing machine removes impurities from sand and gravel to improve their quality and purity. It uses stirring and water flow to wash away soil, dust, and other contaminants from the surface of the sand and gravel, making the finished product meet the standards required for construction or other industrial uses.

A dust collector removes dust and particulate matter generated during industrial production processes, purifying the air and protecting the environment and workers' health. It captures and collects airborne dust through filtration, settling, or other physical and chemical methods, ensuring that the discharged air meets environmental protection standards.

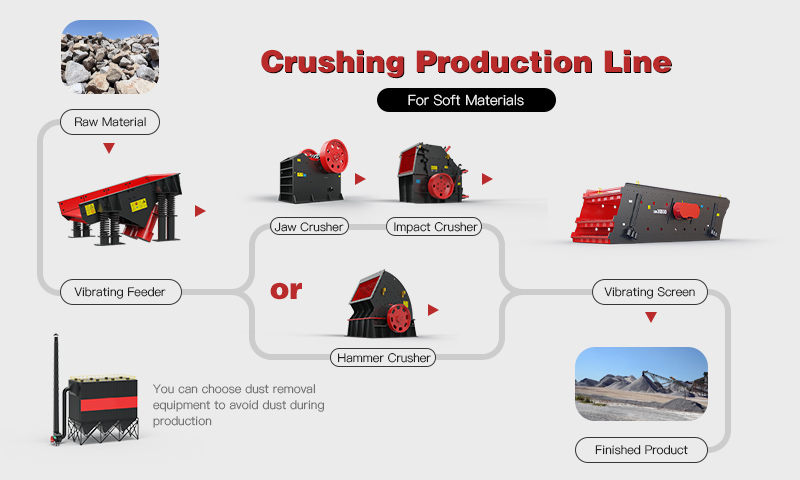

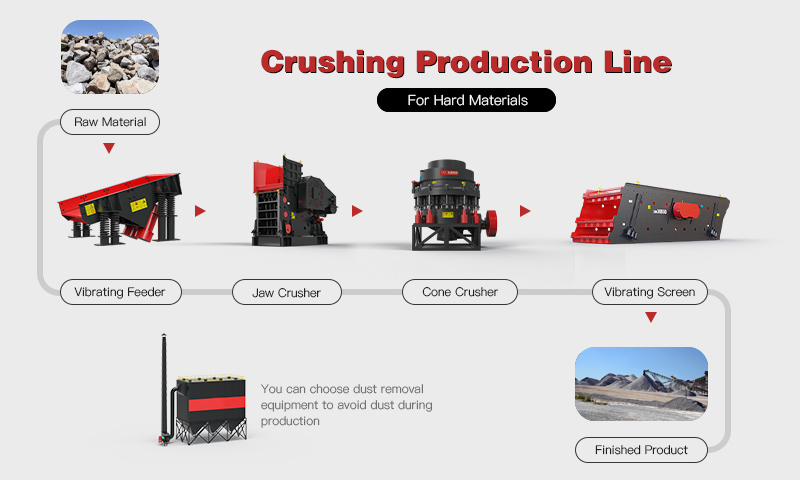

Crushing Production Line

For Soft Materials:

For Hard Materials:

Sand Making Production Line

For Soft Materials:

For Hard Materials: