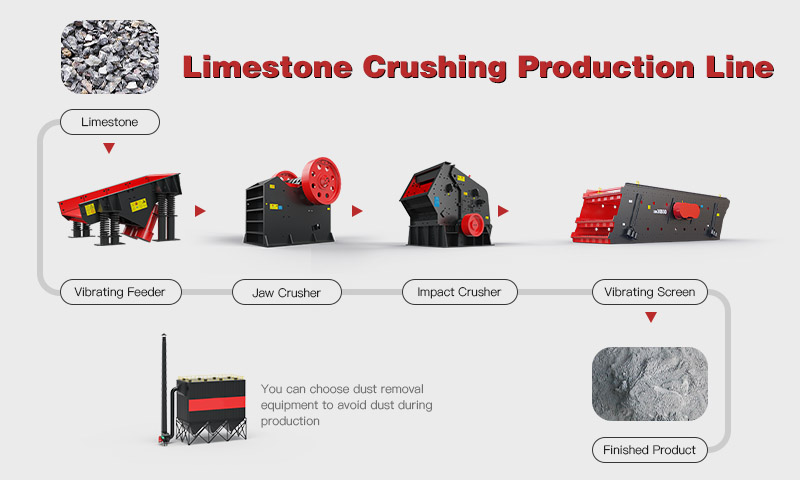

The limestone crushing production line is a crucial step in the lime burning and cement production processes. By utilizing FTM limestone crushing production line equipment, cement plants can crush large pieces of limestone to meet national standards and customer requirements. This equipment ensures a uniform particle size in the crushed products, offers a long service life, produces low noise and dust, is easy to maintain and repair, and generates low vibration.

1.Feeding: Material is transported from the vibrating feeder to the jaw crusher.

2.Primary Crushing: The material is crushed by the jaw crusher.

3.Secondary Crushing: The crushed material is conveyed to the impact crusher equipment for further crushing.

4.Screening: After secondary crushing, the material enters the vibrating screen for screening.

5.Finished Product: The screened material is transported by a conveyor.

6.Re-crushing: Unqualified material is returned to the impact crusher equipment for secondary crushing.

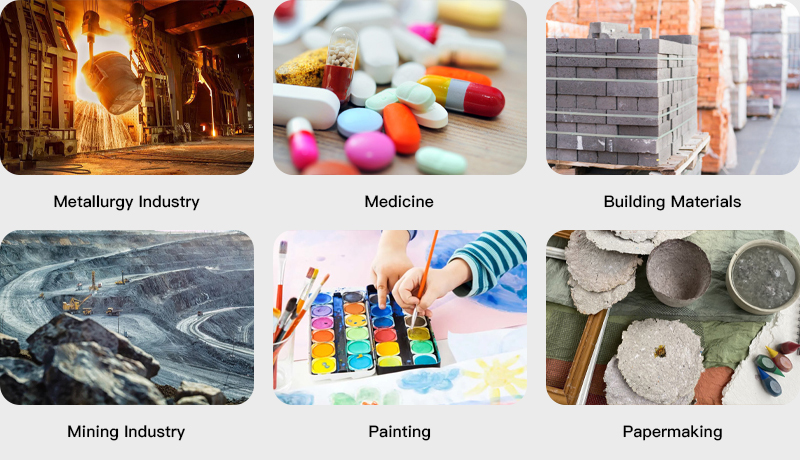

The introduction of foreign high-grade calcium carbonate materials and fillers into the Chinese market has spurred domestic technological progress. This has accelerated the growth of deep-processed calcium carbonate varieties, leading to diversification, specialization, and refinement in the industry, and expanding its application fields. FTM has successfully installed complete sets of crusher production lines for many domestic limestone production line investors, ensuring economic benefits and solidifying its position as a preferred choice for crusher equipment buyers.