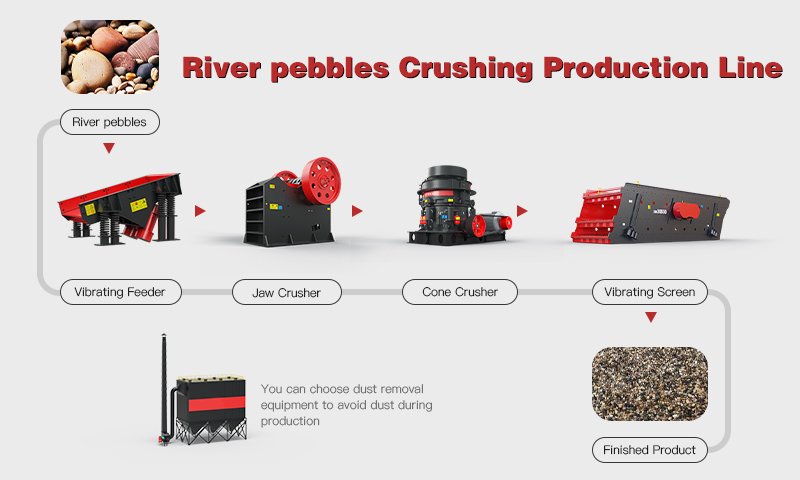

River pebbles are known for their high hardness and strong abrasion resistance, which can lead to significant wear and tear on crushers and sand-making machines during production. To minimize wear costs, it's crucial to configure the production line of pebble and stone processing rationally. A typical configuration involves several stages of crushing and screening to produce high-quality sand and aggregate.

PEBBLE CRUSHING PLANTS DESIGN

1. Feeding: A feeder with a screening function is used to feed the raw materials.

2. Primary Crushing: A jaw crusher is used for the initial break.

3. Secondary Crushing: Jaw crusher or cone crusher is used for the second break.

4. Screening: The shaped material is then passed to screening equipment for partitioning.

5. Re-crushing (if necessary): Materials that do not meet the size requirements are fed back to the shaping equipment, forming a closed crushing cycle.

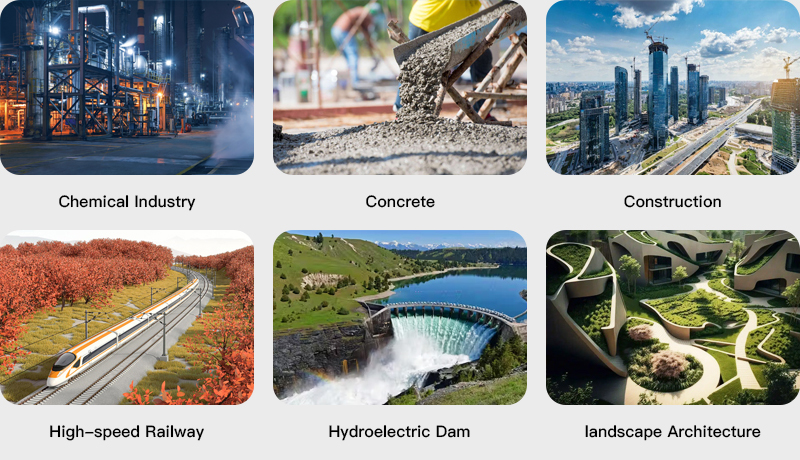

Natural river pebbles undergo several processing steps such as crushing and screening. River pebbles are valuable industrial mineral raw materials, widely used in various construction projects due to their high quality and abundance.

- Abundance and Low Acquisition Cost: River pebbles are rich in resources and relatively inexpensive to acquire.

- High Application Value: They are versatile and widely used in construction due to their strength and durability.

By optimizing the process configuration and leveraging the properties of river pebbles, production lines can achieve efficient, cost-effective production of high-quality sand and aggregates.